This evaluate in the Handle and monitoring actions really should be performed on the store floor by examining get the job done Directions, merchandise acceptance strategies, Command charts, and so on.

three. If evaluation of your Machine History Data (such as process Command and checking documents, acceptance action data, and so on.) reveals which the sterilization process is outside the company's tolerance for running or functionality parameters:

A prompt evaluation of all ideal information relating to aseptic production Because the past profitable APS. The outcome in the critique ought to include things like a hazard assessment of possible sterile breaches in batches produced since the final thriving process simulation.

This Site makes use of cookies to empower, optimise and analyse internet site functions, along with to offer personalised information and permit you to connect with social media. By clicking "I concur" you consent to the usage of cookies for non-critical features along with the associated processing of private details.

The failure Evaluation of many different solutions will involve the use of the next resources and tactics:

Overview the particular process(s) to the sterilization process selected and the procedures for controlling and monitoring the process. Confirm the process is controlled and monitored.

(four) An announcement of some other function essential to the particular sterility website test technique to make sure steady and accurate benefits.

(three) The sterility test and test factors has to be confirmed to show that the test strategy can consistently detect the presence of viable contaminating microorganisms.

Utilizing the sampling tables, pick several schooling and qualification documents for process operators and employees conducting Q.C. functions associated with the sterilization process. Wherever a process is operated in excess of multiple change, teaching information from all shifts needs to be included within your overview.

Validated sterilization parameters are certainly not incorporated in standard working processes, developing a probability of using a non-validated sterilization cycle.

Why is sterility testing executed for fourteen days? The sterility assay is fourteen times permitting for an acceptable incubation period to detect slower-escalating microorganisms. Even though lots of bacterial and fungal organisms may be detected inside of a shorter incubation period of time, some microorganisms require a for a longer period incubation period of time to proliferate.

This process must be documented and communicated over the Corporation. Ensure there are described triggers that initiate the RCFA process, like a major equipment breakdown or perhaps a recurring high quality issue.

As advances while in the cell therapy area continue on to development as a result of tutorial medical trials and hospital pharmacies keep on to rely upon on-web page laboratories for environmental monitoring cultures of controlled compounding regions, it is click here necessary that scientific microbiology laboratories Use a sound comprehension of the main regulations and practices governing microbiological testing in the biopharmaceutical market. We compose from our working experience within the NIH Scientific Heart and provide Perception right into a program where product sterility testing and environmental checking practices have been regime inside the scientific microbiology laboratory until situations in 2015 (12, 13) prompted Management to acquire a sturdy and holistic cGMP application with a individual testing laboratory dedicated exclusively to cGMP functions.

____________________________________________________________________________________

Edward Furlong Then & Now!

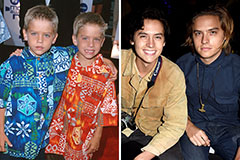

Edward Furlong Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Michael Bower Then & Now!

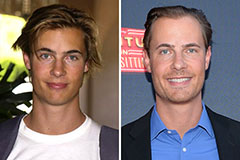

Michael Bower Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now!